You’ll love our Direct to Film (DTF) printing services for t-shirts, clothing, and other fabric products. DTF is one of the most versatile and advanced printing technologies, providing high-quality, durable prints on a wide range of fabrics. If you’re customizing apparel for a special event, business branding, or personal use, DTF delivers vibrant designs with superior detail and durability.

What is Direct to Film (DTF) Printing?

Direct to Film printing is a process where special inks are applied directly onto a film transfer, which is then heat-pressed onto the fabric.

Unlike traditional printing methods, DTF allows for full-color, photo-realistic designs to be printed on virtually any type of material, including cotton, polyester, blends, and even synthetics like nylon. This method offers exceptional flexibility, making it ideal for printing complex and colorful designs.

DTF Printing Benefits for Custom Apparel

Flexibility with Fabrics

One of the biggest advantages of DTF printing is its ability to print on a wide range of fabrics. Whether you need designs on cotton, polyester, blends, spandex, or even hard-to-print synthetic fabrics, DTF is the perfect solution.

Photo-Realistic Designs

DTF printing allows for detailed, full-color designs with smooth gradients, vivid colors, and even photographic quality. It’s an excellent choice for complex designs with multiple colors and intricate details.

Durability

DTF prints are highly durable, with excellent washability and resistance to cracking or fading. The adhesive used in the DTF process ensures a strong bond to the fabric, making these designs last through regular wear and laundering.

Cost-Effective for Small and Large Orders

DTF is ideal for both small batch orders and large runs. This makes it a great choice for personal projects, events, or businesses that need custom apparel without the high setup costs associated with other methods.

Versatile Applications

DTF works well for all types of apparel—t-shirts, hoodies, hats, bags, and more. Whether you’re creating merchandise for your business or custom gear for an event, DTF delivers high-quality results every time.

DTF vs. Direct to Garment (DTG) vs. Heat Press Printing

Direct to Film (DTF) vs. Direct to Garment (DTG)

Both DTF and DTG are methods of printing directly onto fabric, but they differ in how the ink is applied and transferred. DTG prints the design directly onto the garment using specialized printers. While DTG works best on cotton fabrics and is great for high-detail, colorful designs, it’s limited in terms of the fabrics it can print on.

DTF, on the other hand, prints the design onto a transfer film before applying it to the fabric. This allows DTF to work on a much wider range of fabrics (such as polyester, nylon, and blends) and creates a more durable bond, making it more versatile and long-lasting than DTG.

DTF vs. Heat Press Vinyl (HTV)

While both DTF and HTV involve heat application, they are quite different processes. Heat Transfer Vinyl uses sheets of colored vinyl that are cut into shapes or designs and heat-pressed onto the fabric. HTV is great for bold, single-color designs or text, but it can be more limited in terms of complexity and color variety.

DTF allows for full-color, intricate designs with smooth transitions between colors, making it ideal for more complex artwork and high-detail prints. If you’re looking for photo-quality prints or detailed logos, DTF is the better choice.

Which Option Is Best For You?

For simple, bold designs with one or two colors, HTV might be your best bet. However, if you’re looking for detailed, full-color designs on a wide range of fabrics, DTF is the superior choice due to its versatility, durability, and ability to print complex images.

Why Choose Royal Stitch and Print for DTF Services?

At Royal Stitch and Print, we pride ourselves on delivering exceptional quality with every order. Our DTF printing services offer the perfect solution for businesses, organizations, or individuals looking for vibrant, durable custom apparel. Whether you need branded clothing for your company, event merchandise, or personalized gifts, our DTF services ensure you receive the best possible results—every time.

The DTF Process at Royal Stitch and Print

- Design Creation: At the start of the DTF process, we work with you to create or fine-tune your custom design. Whether it’s a logo, graphic, or text-based design, we ensure that it’s print-ready and optimized for the DTF process.

- Film Printing: Using a specialized printer, we print your design directly onto a high-quality PET (polyethylene terephthalate) film. The print includes a layer of adhesive powder that ensures your design will bond securely to the fabric.

- Powdering: After the ink is applied to the film, a heat-activated adhesive powder is added to the design. This powder allows the design to adhere firmly to the fabric during the heat transfer process.

- Curing: The printed and powdered film is passed through a curing process that prepares it for transfer to the garment. This step ensures the ink and adhesive are stable and ready for application.

- Heat Transfer: The cured film is then placed onto the garment, and a heat press is used to transfer the design. The combination of heat and pressure permanently bonds the ink to the fabric, resulting in a durable, high-quality print.

- Peeling: After the heat press is complete, the film is carefully peeled away, leaving the design perfectly transferred onto the apparel. The result is a vibrant, long-lasting print that can withstand repeated washing and wear.

Get started with your custom apparel project today by contacting us at Royal Stitch and Print! We’re here to help bring your designs to life with the cutting-edge technology of DTF printing.

Questions about DTF or any of Our apparel Printing services?

Call 732-963-7077 or Contact Us to speak with an expert

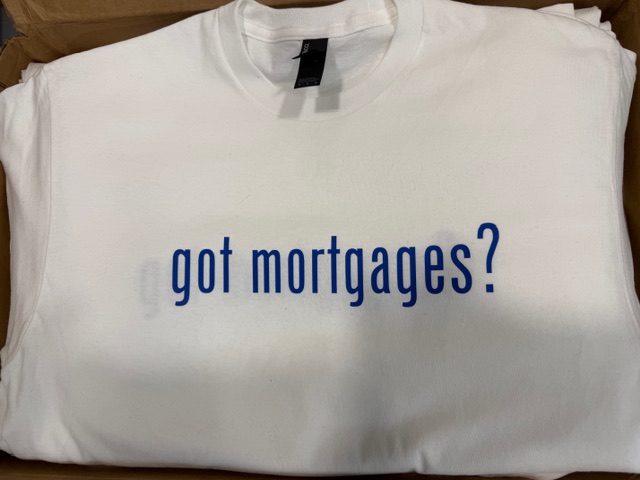

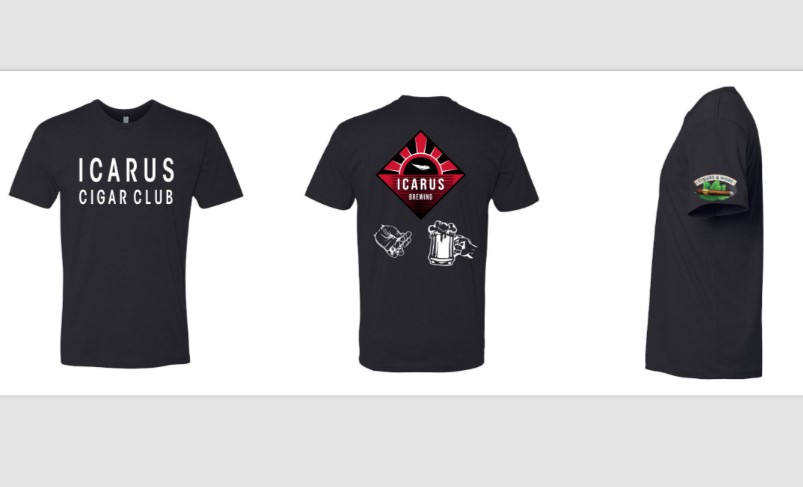

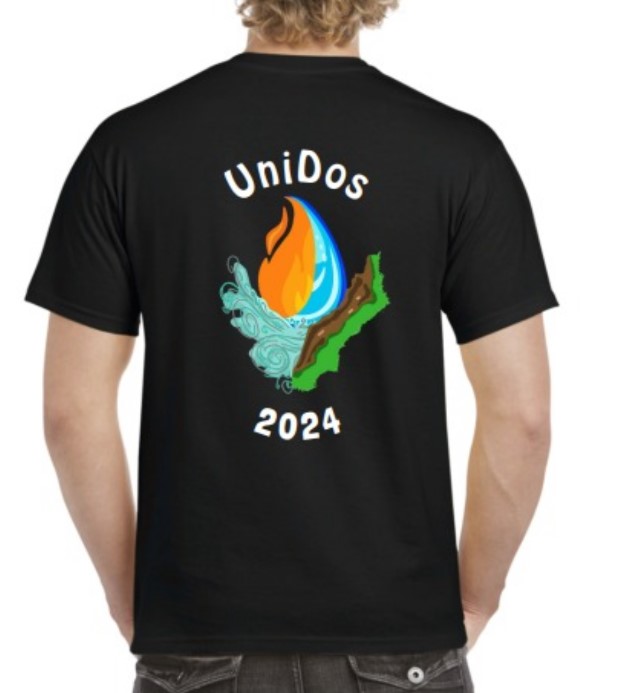

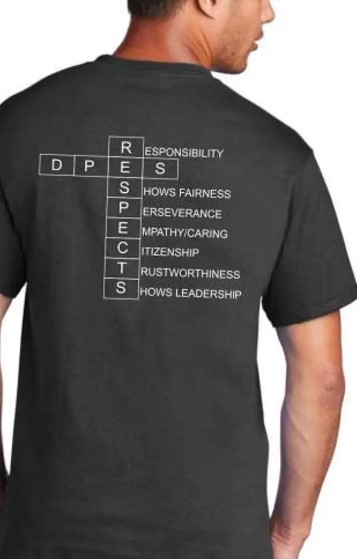

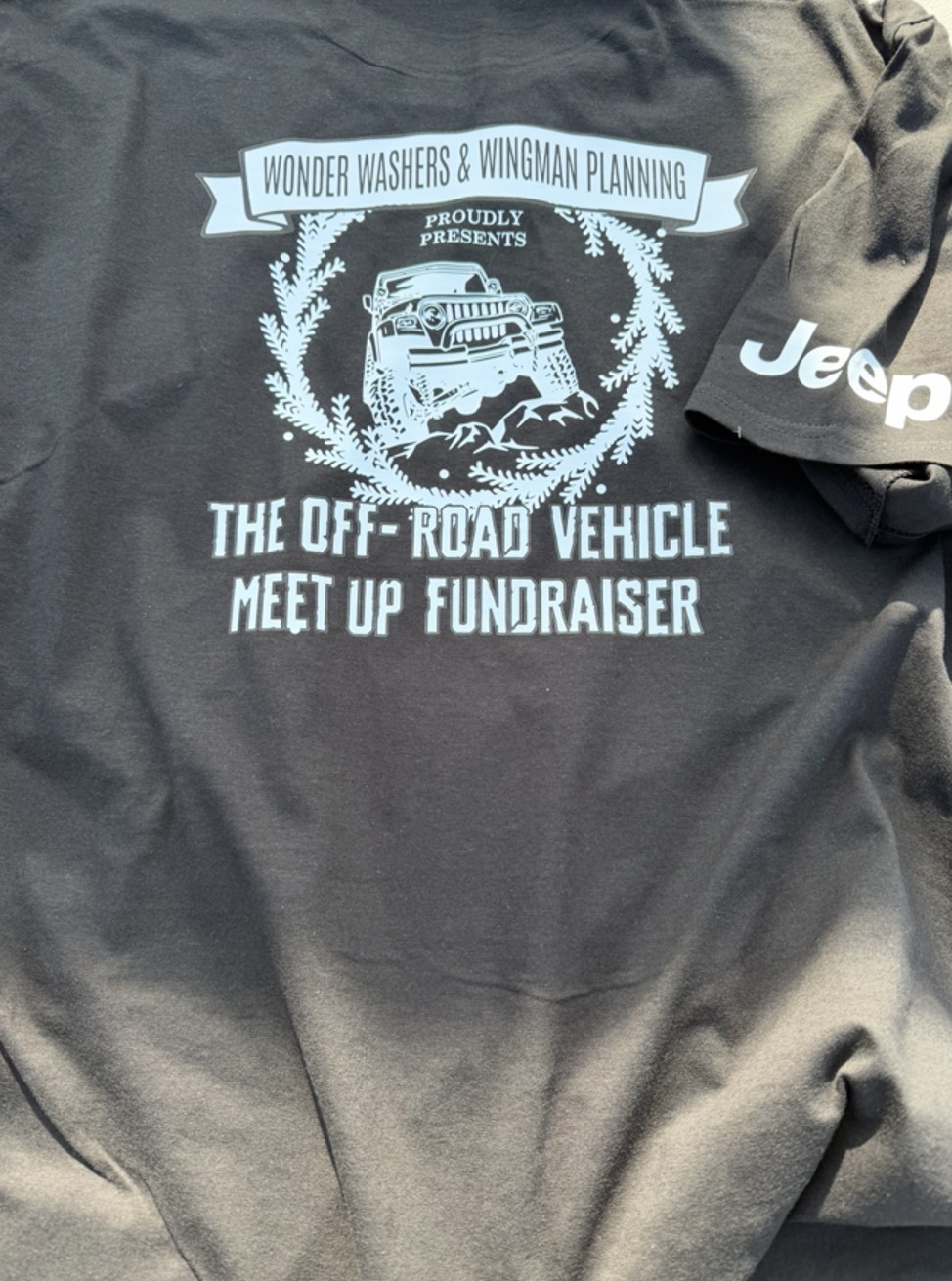

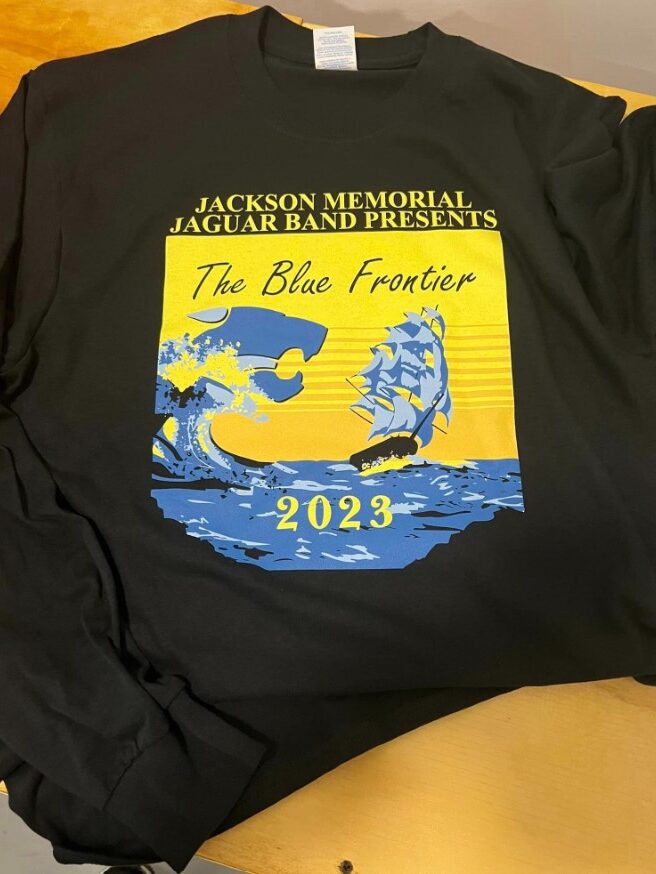

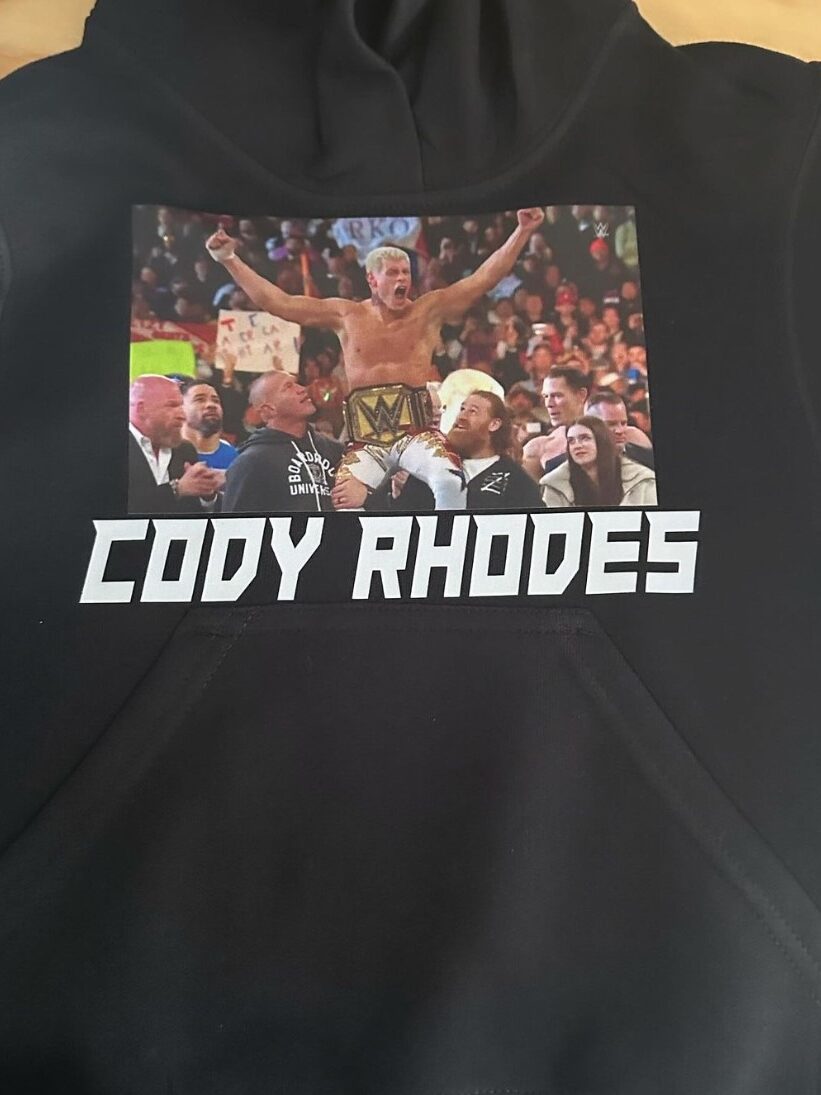

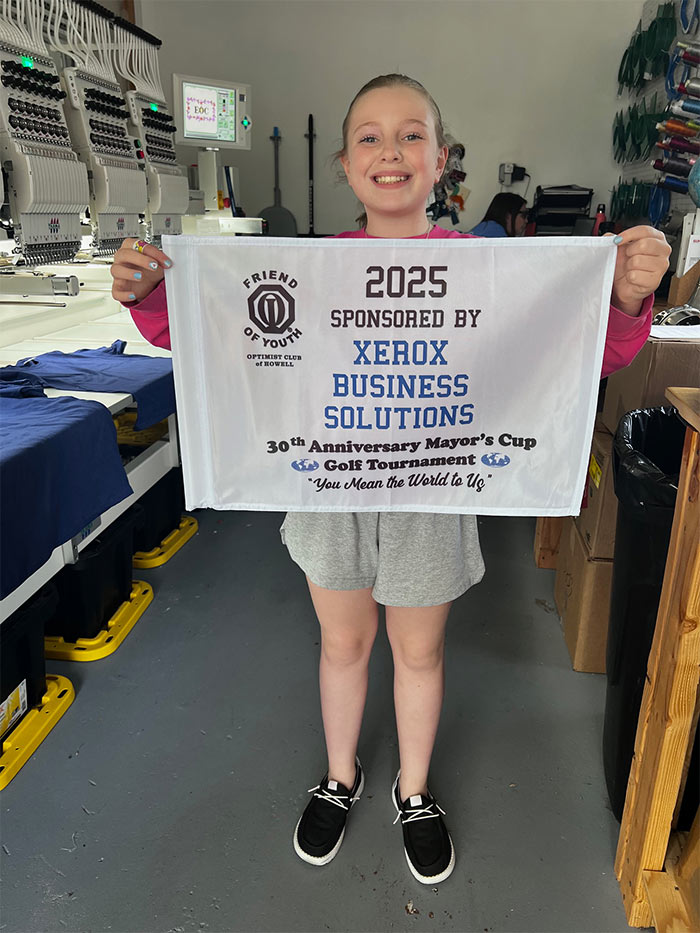

Click on an image below to view the larger picture